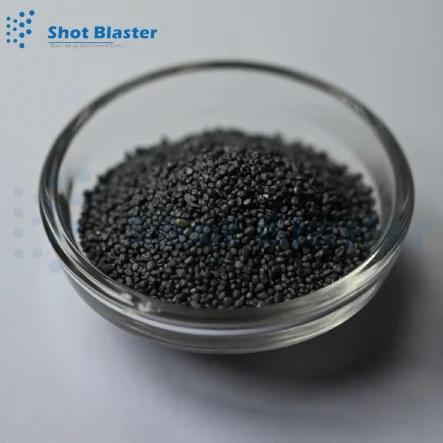

Tungsten Grit

Long-lasting tungsten carbide grit produces overly clean, smooth cuts via tile, cement representatives, & further abrasive media. tungsten carbide grit is excellent for cutting holes in quartzite chamber & hardy panel siding for 3-0 box structure. Our crushed tungsten carbide is strained to complete an assortment of additional specifications & sizing requirements. Crushed tungsten is assembled of tungsten carbide grit chaperoned by a cobalt binder for welding applications.

The chemical combination of carbon atoms & tungsten grit atoms is understood as tungsten carbide grit. Tungsten carbide could be engaged to assemble jewelry, cutting tools, abrasives, industrial equipment, armor-piercing shells, & abrasive media. In its significant superficial form, it is an acceptable grey tungsten carbide powder. However, it could be compressed & developed into shapes by a process named sintering. Tungsten carbide is constantly engaged to assemble wedding rings. Tungsten carbide rings are substantially more enduring than gold & silver rings. On the Mohs hardness scale, tungsten rings are placed betwixt 8-9.

A hexagonal shape of WC lives, furthermore a cubic elevated warmth form, tungsten carbide, chaperoned by a gravel salt configuration. Hexagonal structure is constructed up of a straight hexagonal lattice of metal bits of thermal spray gun coatings fibbing presently over one a further, hence, not near packed), accompanied by carbon atoms refilling 1/2 interstices, delivering either tungsten & carbon a standard ternary prismatic, 6 cooperativeness. Adhesive lengths betwixt tungsten scraps in a hexagonally filled coating are 291 pm, the quickest space betwixt tungsten atoms in nearest coatings is 284 pm, & tungsten carbon adhesive measurement is 220 pm, based on the team enclosure dimensions. Length of tungsten-carbon adhesive is consequently identical to the single adhesive in W(CH3)6 (218 pm), in whichever tungsten is positively turned ternary prismatically similar to.

The most often used material for machining tools nowadays is tungsten carbide, although other materials and coatings are also widely employed. Understanding the differences between tungsten carbide, steel grit, and other abrasive media is crucial when recycling waste metal tools since some of them can be recycled while others cannot. Furthermore, certain materials are far more valuable than others.

In the specialization of wear aspects, tungsten carbide faces competition from evolved ceramics. However, just as mechanism steel was not replaced by advanced ceramics, tungsten carbide cannot be superseded by advanced ceramics. Explanation is certain, given its heightened hardness, tungsten carbide contains exceptional toughness, whichever has permitted it to see remarkable expansion as a tooling & engineering material.

Properties of Tungsten Carbide

- Tungsten carbide retains an increased melting point of 2,870C (5,200F).

- It contains a boiling point of 6,000C (10,830F).

- The thermal gravity increased to 110 Wm-1K-1 at 1 occurrence (100 kPa).

- It exhibits a 5.5 m·m-1·K-1 thermal rise. Tungsten carbide material is used for tungsten carbide coating.

- With a remarkable hardness of roughly 2600 & a Mohs hardness of 9–9.5, tungsten carbide is incredibly rigid.

- Shear modulus is approximately 274 GPa, majority modulus is roughly 630–655 GPa, & Young's modulus is roughly 530–700 GPa.

- It contains a poisson's percentage of 0.31 & contains most elevated tensile solidity of 344 MPa, & most elevated squeezing stability of roughly 2.7 GPa.

- A longitudinal wave transiting via a narrow rod of tungsten carbide transits at 6220 m/s.

- Tungsten carbide's significantly inferior electrical resistivity (of roughly 0.2 m) is proximate to a few specific metals.

- Tungsten carbide is easily watered by either molten nickel & cobalt. W-C-Co procedure degree diagram indicates certain WC & Co. continue to maintain a pseudo-binary eutectic.

- Because carbides can form & these stages are brittle, overseeing the carbon range in WC-Co cemented carbides is essential.

- Abnormal grain elaboration holds been followed in sintering of tungsten carbide in existence of a molten phase, similar to cobalt, & is crucial to effectiveness of final material.

Non-Magnetic Cast Tungsten Carbide Grit

A eutectic mixture of W2C & tungsten metal is assembled by melting tungsten metal & tungsten monocarbide (WC) jointly. This melt is assembled into exceptionally difficult solid bits with a tiny crystal arrangement by casting it & quickly quenching it. After existing crushed, solids are divided into different mesh sizes. Melting tungsten metal and carbon together produces casting tungsten carbide powder. WC and W2C are its two eutectic compositions. By quenching, the melt is transformed into incredibly hard solid particles with a fine crystal structure.

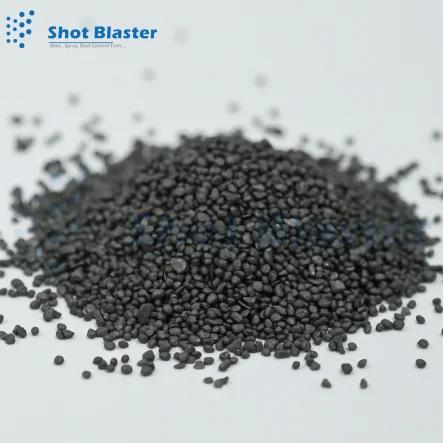

Welding Grade Carbide Grit

Formulated of cobalt-bindered tungsten carbide grit for usefulness in welding operations. We screen our ground tungsten carbide to ensure certain it satisfies a spectrum of standards for size & specifications. For welding applications, tungsten carbide is associated attended by a cobalt binder to create granular tungsten. The end outcome is a tungsten carbide replenished weld assurance encased in a mechanism steel matrix.

In addition, we provide many different abrasive media for surface preparation, cleaning, & finishing applications, including stainless steel shots, glass beads, commercial aluminum oxide, plastic media, copper slag, quartz sand & cut wire shots.

Brazing grade Carbide Grit

Composed of cobalt-bindered sintered tungsten carbide for use in welding operations. We screen our crushed tungsten carbide to ensure that it satisfies a range of standards for size and specifications. For welding applications, sintered tungsten carbide is combined with a cobalt binder to create crushed tungsten. In the application procedure, the pulverized tungsten particles are introduced into a molten pool of weld just before the pool freezes. The end product is a tungsten carbide-filled weld deposit encased in a tool steel matrix.

Tungsten Carbide Grit Supplier

We are the leading tungsten grit manufacturer and also tungsten carbide grit supplier in India. We offer all types of abrasive blasting machine, sand blasting machine, sand blasting cabinets, wet blasting machines, suction blaster, bench top sand blasting cabinet, blast room systems, stone shot blasting machine, laser rust cleaning machines, grit blasting machines, sand blasting spare part, sand blasting nozzle, sand blasting helmet, mixing tube, remote control valve, granite engraving machine, thermal spray gun paint spray booth, thermal spray powder, thermal spray wire, abrasive media, garnet sand, stainless steel shot, cast steel grit, brown aluminum oxide, quartz silica sand, PS ball etc.