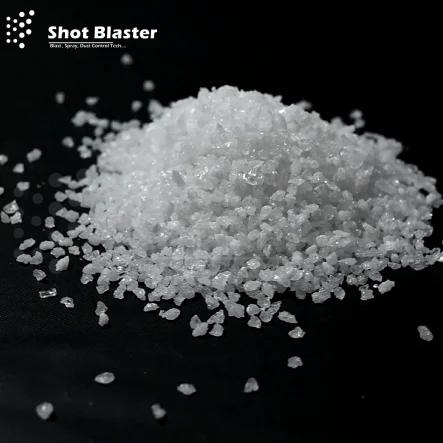

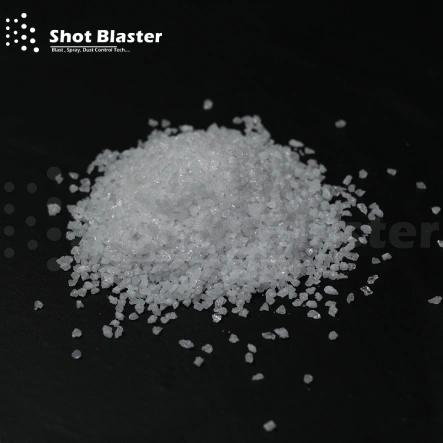

Aluminum Oxide Grit

Aluminum Oxide Grit is a sharp, long-lasting abrasive media that is highly efficient and highly reusable/recyclable thus cost-effective in nature. Harder than most blast media, Aluminum Oxide Blast Media, the powder will clean and etch quickly on all types of surfaces. Grits of this abrasive media are best for preparing the surface for the polishing and coating of blasting surfaces. It is also used often for surface cleaning because of the rugged nature of this blasting media. The small grit particles and powder strike the area with compression and clean hard corners easily. Approximately it is 50% lighter weight blasting media than metallic media, aluminum oxide abrasive grain has twice the number of particles per pound. The fast-cutting action of aluminum oxide grit minimizes damage to thin materials by eliminating surface stresses caused by heavier, slower cutting media.

Aluminum Oxide Specifications

| Abrasive Material |

Corundum (Virgin Grade) |

| Aluminum Oxide Content |

95 % Min |

| Hardness On Moh's Scale |

09 Min |

| Specific Gravity |

3.9 Min |

| Melting Point |

2,072 degree C |

| Molar Mass |

101.96 g/mol |

| Packaging Size |

50 kg |

Aluminum Oxide Exporter in India

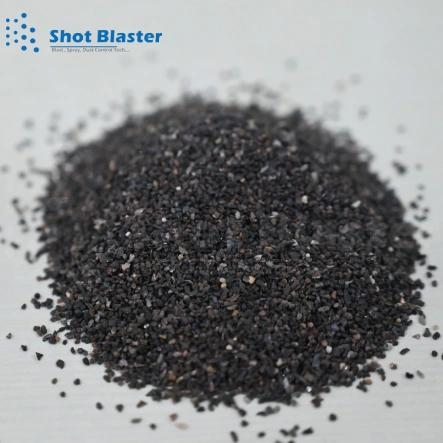

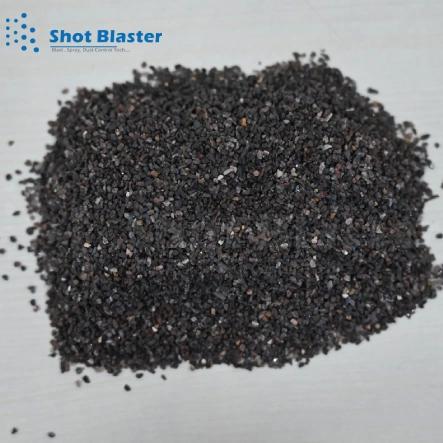

We are the manufacturer and exporter of a competitive range of aluminum oxide supplier (Commercial aluminum oxide & Special Grade), which is an amphoteric oxide of aluminum. These products are available all together in grit types and are widely utilized in different industries for various applications. Our products are tested on the idea of various parameters and are available in several specifications. we provide these products at very affordable prices and these products are available in Brownish Black Color.

Aluminum oxide is the reasonable surface of the substrate at twofold the speed as sand without all the prosperity risk. Aluminum oxide is accessible in two kinds one is virgin grit and the second is business grit. Virgin grit can be reuse more than 6-7 times without any problem. Also, business grit is utilized 2-3 times. Aluminum oxide delivers less residue while use. Virgin aluminum oxide is more costly than business grit.

Aluminum oxide can be utilized effectively in versatile blasting machines and wheel blasting machines. To gather and reuse aluminum oxide generally blasting cupboards and impact room frameworks are utilized. Inconvenient blasting machines cleaning or blasting done in an open zone so it is difficult to gather blasting media for reuse. Spout size is additionally thought of while picking aluminum oxide size for blasting. The size of blasting media use relies on the size of the spout. On the off chance that aluminum oxide size is huge, it makes chock the spout and blasting not done.

Aluminum oxide use in both dry blasting cabinets and wet blasting cabinets since aluminum oxide sway media is known for its high thickness and high sharpness which makes it among the most versatile of the affecting media types. Aluminum oxide blasting abrasively accessible in much standard size to meet any surface readiness and completing prerequisites in both virgin and business types. Aluminum oxide is lighter in weight than other metallic blasting media. Because of its lightweight aluminum oxide unpleasant grain has a double similar number of particles per pound. Aluminum oxides have an angular shape and have high hardness. Aluminum oxide is a forceful grating blasting media that is reasonable for both ferrous and non-ferrous substrates.

Chemical Properties of Aluminum Oxide supplier

| aluminum oxide( Al2O3 ) |

94. 00 % |

| ferric oxide ( Fe2O3 ) |

1. 28 % |

| silica ( Sio2 ) |

2. 26 % |

| calcium oxide ( CaO ) |

0. 22 % |

| magnesium oxide ( MgO ) |

traces |

| titanium oxide ( TiO2 ) |

0. 79 % |

| loss of ignition |

0. 45 % |

Some Important Details

- Delivery Time- Minimum Time

- Port of Dispatch- All India Port

- Production Capacity- 3000 MT Per Month

- Payment Terms- L/C(Letter of Credit)T/T(Bank Transfer)/D/P/D/A

Blasting Applications of Aluminum Oxide

- Drawing Metal.

- Paint Stripping.

- Preparing Surfaces for Coatings.

- Landmark Etching.

- Cleaning Discoloration From Welding.

- Surface Prep for Metalizing and Welding.

- The groundwork for Bonding.

Aluminum Oxide Supplier in India

We offer an abrasive shot, Steel Shot, SS Shot, Steel Grit, Garnet sand, Quartz shot, Aluminum oxide, glass beads blasting for stainless steel, etc, and a qualitative range of industrial steel abrasive products. We provide a large range of products and are checked on various parameters, such as density, physical and chemical properties, microstructure, hardness, durability. We are focused on our quality products and customer satisfaction.

To enable us to quote for your requirement, kindly give us the following info –

1. Particle size required (You may choose from above or give your own range).

2. Packing required.

3. Quantity required with the delivery schedule.

4. Destination port.

5. Payment terms.

6. Discharge rate at the destination, if in break-bulk.

7. Any other point which may impact the quote.

We can also offer ungraded material for shipments in bulk in any quantities as desired by our buyers on FOB or CNF FO basis terms.