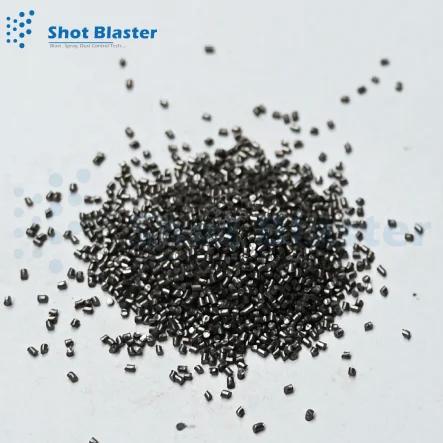

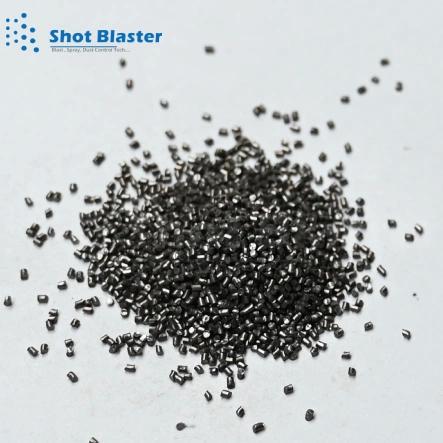

High Carbon Cut Wire Shot is used for shot peening as a precision tool. It is produced by special cutting machines with carbon steel wire of the chosen diameter and tensile strength. It is the preliminary stage of conditioned cut wire pellets and fulfills the specification. We are the leading producer, manufacturer, suppliers, and exporters of high carbon wire shots. We manufactured the high-quality product by cutting wires into equal length to the wire of diameter or width.

The quality of shots is controlled by chemical and physical properties present in the wire and accurate cutting to lengths. Every high carbon shot is 100% solid in nature or naturally. These cut wires are available in a cylindrical or spherical shape or form in several sizes from 0.30 mm to 3.17 mm. High Carbon Wire Shot applications include Shot peening, blast cleaning, tumbling and finishing Blasting, Dust removal paint removal. These are generally blackish, hard in nature, and made from high carbon of cut wire.

Features of High Carbon Cut Wire Shots

High carbon cut wire is used in sand blasting the use of High carbon is for coating on sand blasted material like train blocks, granite, cooler, tanks, etc. High carbon helps sandblast and remove the coating from the workpiece. The High carbon steel cut wire is used for sand blasting first and then it is used for coating through a thermal spray gun.

Also If you are interested in Low Carbon Cut Wire Shots

Application where the use of cut wire shots are:-

- Surface finishing

- Smoothening

- Shot Blasting Machines

- Grit Blasting

- Sand Blasting

- Shot Peening

- Blast Cleaning

- Rust Removal

- Paint Removal

The Cut wire shots are used in sand blasting which helps to remove all the above types of the machine it can also be used in coating where the used coating. In sand blasting machines all types of cuts of wire are taken in use to form all dust particles or remove things.

The Advantages of High Carbon Cut Wire Shots

- Most economical

- lowest consumption

- No dust formation

- Faster cleaning

- Environmental friendly

- Uniform hardness

- the Increased fatigue life of blasted parts

- Stabilized grain size

All the cut wires are available in different sizes or mm. As well shape or size as per-use all the grain size of cut wire is available different hardness, tensile density, strength, etc.

Manufacturers of High Carbon Cut Wire Shots in India

Sand Blast is the leading producer and supplier of high-quality Shots in India. Check the prices of High Carbon Cut Wire Shots by getting in touch with us. We are manufacturers of all types of sand blasting machines and shots and abrasives which are used in sand blasting machines at the best price in Jodhpur, India.