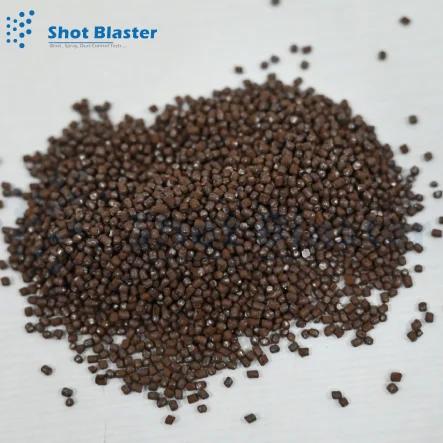

Cut Wire Shot Manufacturer

Cut Wire Shot is the media of preference for peening, cleaning, tumbling, and vibratory finishing. It is widely used in wheel blast equipment. It can be of two shapes as-cut (cylindrical with sharp edges) or conditioned (rounded to a sphere). Cut wire shot is blasting media used in shot blasting machine for the surface preparation process. Cut Wire Shot has a high content of carbon because they are made of cold drawn spring steel. Cut wire shots are obtained by cutting wire into length equal to the diameter of the wire, and if necessary then make them round through conditioning or rounding process. Cut wire shot assured the quality because the wire used to produce shots is heat-treated and cold drawn to achieve homogeneity and hardness. Cut wire shot have some chemical and physical properties which insure complete solidity of every piece and ensure that cut wire shot will not fracture, break or powder while in use.

Cut wire shot has a sharp edge due to this cut wire shot are used for good cleaning where the speed of cleaning is critical and rough finishing is acceptable. Cut wire shot use in shot blasting machine in which wheel rotates and the shot blasting machine process is formed throw cut wire on the surface of the component. To rotate the wheel electric motor is used. In an airless blasting machine size of the wheel varies and with the wheel size, cabinet size varies also. The size of the cabin depends upon the component dimensions. Cut wire shots not produced dust during the blasting process and can be reused many times.

Cut wire shot available in various hardness ranges depends upon the application. Usually higher the hardness of cut wire shot lower the durability. Surface cleaned by cut wire shot shows exceptionally more bright and smooth results after blasting.

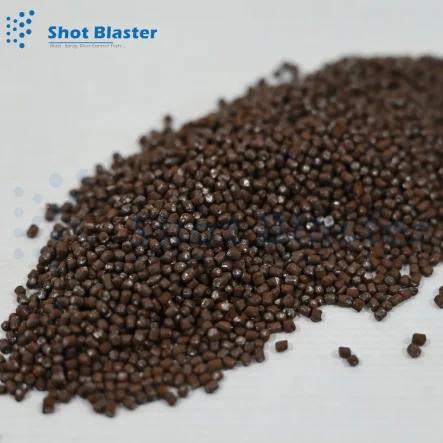

| Shape |

Round |

| Size |

0.40-2.50 mm |

| Color |

Grey |

| Packaging Type |

Bag |

| Density |

Up to 7.8 cm³ |

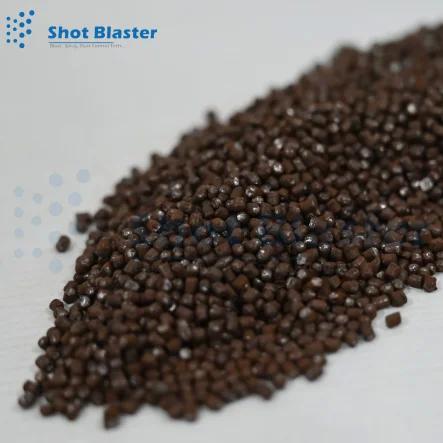

Features of Cut Wire Shot manufacturer

- Its cylindrical shape with edges rounded helps in fast cleaning. The blasting machine’s rate of cleaning increase 25% from the actual cleaning rate.

- TO blast 1 ton of material 1.5 kg of cut wire shot is required were approx 4 kg shot required cleaning 1-ton material.

- Cut wire shot has excellent homogeneity; also, they have equal size and hardness.

- Cut wire shots have a natural tendency to become spherical after a few hours of use in the shot blasting process.

- Cut fire shots have fine grain size due to these shots reuses many times until every shot reduces to microparticles and cut wire shots do not break into dust.

- Components which are a blast with cut wire shots have a much greater life than the component blast with steel grit and steel shots because cut wire shot maintain longer intensity than any other shot or grit type.

- The shot used in the shot blasting process should be at least as hard as the component being blasted.

- Cut wire shots reduce the cost for maintenance and warehouse if uses 3-5 times in a cycle.

- Cut wire shots have low surface contamination.

- 100% solid material; no presence of blowholes, tails & porosity.

- It reduces the time for shot blasting.

- As compared with other blasting media cut wire shot gives fast, bright, and smooth surface finishing.

- Cut wire shot also increases the fatigue life for the blasting component.

- No dust formation during operation of blasting so no health hazard.

Applications of Cut Wire Shot Manufacturer

- Cleaning

- De-burring

- De-scaling

- Fettling

- Shot peening on iron & steel component