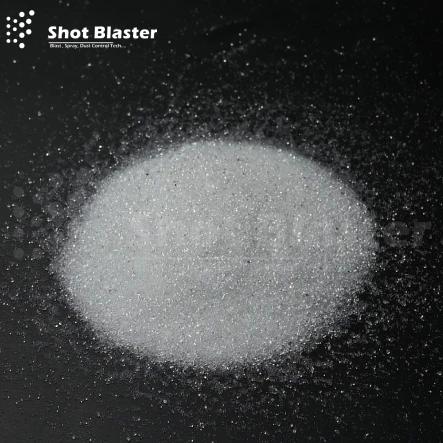

Abrasive Glass Beads Blasting

Glass beads are used in the sand blasting machine for surface preparation. The best results are reached during a, therefore, referred to as a two-stage method. The surface is initial treated by sharp-edged abrasives – mineral or mineral. The surface is unified and cleansed from any dirt, oxides, heat tint once attachment, and light-weight surface inconsistencies. At this stage, treated parts gain an opaque look. Once the blasting method the surface is at risk of scratches or dirt as a result of the fine sharp-edged relief. This can be the rationale why the blasting itself is employed solely as pre-treatment before coat painting. So as to keep up the metal surface, it's polished by glass beads within the second stage of the method.

This stage makes the sharp A-one of the surface spherical and merchandise gain a nice fabric look, which additionally lowers the visibility of any potential injury, scratches, smaller defects once attachment, grinding, or spot attachment. Product surface once glass bead blasting is incredibly elegant due to the soft, satin look at the same time, it raises product´s corrosion resistance. For sharpening of the surface glass or ceramic beads are used (see examples). Individual materials slightly dissent in color and hardness. They are equipped during a big selection of sizes; so, to an excellent extent, it's attainable to influence the ultimate look of a product.

The glass bead is an expensive blasting media so for the recycling of glass beads sand blasting cabinet, benchtop sand blasting cabinet is used. For blasting sand blasting machine, shot blasting machine, grit blasting machine, used to clear surface from rust, old paint and other foreign particles and prepare the surface for another process like painting and thermal spray coating, metalizing coating.

Abrasive Glass Beads Size Range

| Size in Microns |

Designated Name |

Finishing Grade |

Finishing/ Cleaning Grade |

Cleaning/ Peening Grade |

| 600-850 |

A |

|

|

? |

| 425-850 |

BL |

|

|

? |

| 425-600 |

B |

|

|

? |

| 250-425 |

C |

|

? |

? |

| 180-300 |

AB |

|

? |

? |

| 150-250 |

AC |

|

? |

? |

| 106-212 |

AD |

|

? |

? |

| 75-150 |

AF |

? |

? |

|

| 45-90 |

AH |

? |

|

|

| 40-70 |

AI |

? |

|

|

| 1-75 |

AQ |

? |

|

|

Abrasive Glass Beads Applications

- Decorative surface treatment of parts made from chrome steel and noble materials.

- Stainless steel – final surface treatment,

- Aluminum parts – before anodal oxidization or coat painting by clear coat paints,

- Other non-ferrous metals – brass, bronze, copper,

- Pre-treatment before galvanization – nickel and chrome paint.

Abrasive Glass Beads Manufacturer, Supplier in India

We are an Abrasive Glass Beads Manufacturer, Supplier in India with quality and fast delivery. We are the Manufacturer, Supplier & Exporter of Thermal Spray Equipments, arc spray gun, thermal spray gun, flame spray gun, zinc spray gun, sand blasting machine, portable shot blasting machine, shot blasting machine, grit blasting machine, sand blasting cabinet, pressure blasting cabinet, sand blasting hopper, abrasives shots, copper slag, steel shots, abrasive garnet, steel grit, plastic media, cut wire shot, aluminum oxide, zinc metalizing wire, zinc aluminum metalizing wire, aluminium metalizing wire, in Jodhpur, Rajasthan, India at a reasonable price for sale.