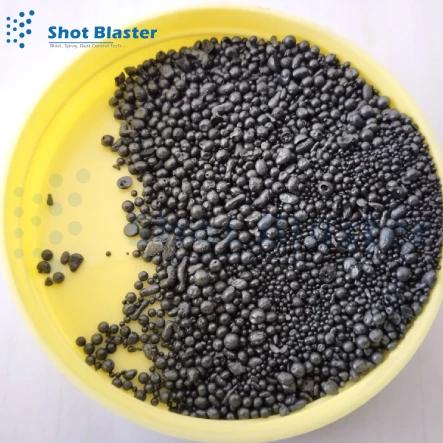

PS Ball Manufacturer

PS Ball stands for Precious Slag Ball, which is an innovative material that can be produced by the rapid cooling of slag generated from steel making process by means of our own Slag Atomizing Technology (SAT). It has superior characteristics compared to Garnet sand or copper slag in its compressive strength, hardness, and anti weathering. The liquid steel slag stream is transformed into spherical slag balls of various sizes by the supercooling method of molten slag, using fast heat exchange of the falling liquid steel slag in high-speed airflow. During this process (Sand Blasting Machine & Shot Blasting Machine), free CaO and Fe2O3 are scattered to form a solid PS ball manufacturer or Precious Slag Ball manufacturer and thus produced is in a stable Spinel Structure.

Application of PS Ball Manufacturer

- It is being widely utilized in the field of ship repair industries and petroleum refinery plant maintenance for shot blasting purposes, Precious Slag Ball manufacturer itself has shaped during a stable and safe form, not pollutant,s and harder than Sand.

- Less risky to the operators and neighbors, low levels of dangerous contaminants, such as asbestos (in olivine) and arsenic.

- Exhaust fewer dust under normal usage conditions than Garnet.

- Easy use with high productivity without replacing blasting equipment.

- Durability to allow collection, reclamation, and reuse.

- Appropriate grain shape and size for the intended application.

- Low environmental impact during storage, use, and disposal.

- Easy to supply than Copper Slag and Garnet.

Comparison with Other Abrasives

A. Comparison Data with other abrasive

| Content |

PS Ball |

Silica |

Garnet |

Glass Bead |

Steel Ball |

| Gravity |

3.45 |

2.62 |

4.2 |

2.6 |

7.2 |

| Mohs Hardness |

7.5 |

5.5 |

7.5 |

5 |

8.5 |

| Rockwell Hardness |

43 |

30 |

40 |

28 |

50 |

| Brightness |

Very Good |

Normal |

Good |

Normal |

Very Good |

| Reusability |

2~3 |

No |

3~4 |

No |

10~12 |

| Facilities Changeable |

Simply |

Simply |

Simply |

Normal |

Difficult |

| Dispose of Waste Material |

Non-scheduled |

Scheduled |

Scheduled |

Scheduled |

Scheduled |

B. Comparison Data of Performance by particle size

| Test Items |

Test Sizes |

Test Material Sand |

Test Material PS Ball |

Test Material Steel ball |

| Surface Roughness (µm) |

0.4-1.0 mm

1.0-2.0 mm

|

50 µm

70 µm

|

80 µm

145 µm

|

90 µm

220 µm

|

|

Remaining Particle on

the blasted face (mg/m²)

|

0.4-1.0 mm

1.0-2.0 mm

|

350 mg/m²

460 mg/m²

|

92 mg/m²

127 mg/m²

|

15 mg/m²

20 mg/m²

|

Industrial Uses

- Shipbuilding.

- Steel Bridges.

- Heavy Steel Structure.

- Storage Tanks.

PS Ball Manufacturer in India

We provide steel shot, SS shot, copper slag, glass beads, steel grit, garnet sand, quartz shot, aluminum oxide, and precious slag ball manufacturer or ps ball, etc. We provide a large range of products and are checked on various parameters, such as density, physical and chemical properties, microstructure, hardness, durability. We are focused on our quality products and customer satisfaction.