Metalizing Wire Manufacturers in India

Sand blast is a leading metalizing wire manufacturer's in India. The metalizing wire is used in a thermal spray gun to provide a protective thick coating layer on the component. Metalizing wire coatings are provided to increase the life of the equipment used in different application areas. Thermal spray coating provides protection from rust, oxidation to the parts used in sea and open environments. The metalizing wire is utilized in different types of thermal spray guns for the coating. We are metalizing wire manufacturer in India and provides metalizing wire price in India for sale at very low compared to other metalizing wire manufacturer's.

Metalizing Wire for Sale

Thermal spray metalizing wire for sale coating providing over the surface with a distinct methodology. Thermal spraying is finished to extend the lifetime of different components and provide resistance against corrosion in even the toughest condition. Before metalizing wires coating, it is required to prepare the component surface and remove loose particles, burs, and other impurities. For surface preparation sand blasting machine, grit blasting machine, sandblasting hopper, shot blasting machine is used. For blasting various types of abrasives like aluminum oxide, glass beads, copper slag, steel grit, steel shots, and abrasive garnet are used as per requirement. Metalizing wire in India is available in various sizes and in alloy form also. We manufacture provide metalizing wire price in Pune, Delhi, Ahmedabad, Jodhpur, Jaipur, Rajasthan, Faridabad, India.

Types of Metalizing Wire

Zinc Metalizing Wire

Zinc metalizing wire coating is most likely to be used in areas where little voids and uncoated areas are not easily accessible. Zinc wire coating has different resistance in water as per the pH scale range. Zinc wires having poor resistance in any water higher than sixty degrees. Zinc metalizing wires coating has poor resistance to most organic and inorganic acids. Zinc metalizing wire in India is generally used on glass and ceramics as a primer to create electrically semi-conductive surfaces. Metalizing wire price changes according to the size of metalizing wire for sale.

Aluminium Metalizing Wire

An aluminium metalizing wire in India is a metal coating material and drawn to a spread of diameter to be used during a flame applicator and arc applicator system. In a flame spray gun, oxygen and acetylene gas are used and in an arc spray gun is used with a power source. Compressed air uses in both types of guns to strike feed metalizing wire. Aluminum wire has helpful features that embody resistance to the atmosphere, chemical, and warmth corrosion. Metalizing wire manufacturers tend to make a thick layer that protects it from additional attacks.

Aluminum metalizing wire coatings provide resistance against cathodic corrosion in atmospheric and salt/freshwater immersion, with varying application areas like oil purification instrumentation, chemical process instrumentation, and ship exposed to seawater, and other similar kinds of exposure. It will increase the lifetime of any equipment by 15-50 years while no maintenance is done.

Babbitt Metalizing Wire

Babbitt metalizing wire applied for thermal spray coating is an alloy metalizing wire of tin. Babbitt wire has laborious and soft compositions that provide resistance to friction & good low wear. Babbitt metalizing wire in India are mostly used in the protection of the food processing tank and produce a dense coating layer of zero.25 to 0.65 metric linear units over the component. Babbitt wire freezing point is very high. Babbitt metalizing wire for sale is employed in the high duty and high-speed bearings.

Molybdenum Metalizing Wire

Molybdenum metalizing wire coatings are employed for high load vehicles because they resist high mechanical masses. A molybdenum wire layer unit sprayed on vehicles and widely used on slippery elements in machines and vehicles. Molybdenum metalizing wires coating is mostly used in shift forks, measuring devices, piston rings, synchronizing assemblies, and different vehicles and machine elements by thermal spray gun. The molybdenum wire is utilized in the form of alloy wire to produce the protective coating for the much-supported application. Molybdenum metalizing wire price is very high as compared to other metalizing wire for sale.

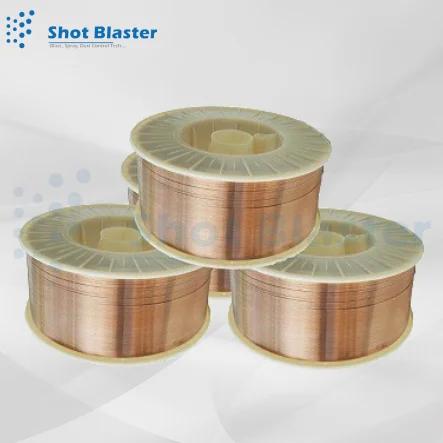

Copper Metalizing Wire

The copper metalizing wire in India is a metal spray coating wire that provides resistance to corrosion in open environment conditions. Copper wire is generally used to provide resistance on the part surface to neutral atmospheric conditions and sea-water environments. Copper metalizing wire for sale having good thermal conductivity & electrical conductivity. Copper metalizing wires in India are used in the thermal spray process for restoration, particularly on copper alloy equipment, in electrical applications components where a coating is required with good conductivity.

Metalizing Wire Coating Application

- Atmospheric and corrosion protection on steel or iron structures such as railway bridges, roadway barriers, posts and poles, offshore structures, and marine structures.

- Atmospheric corrosion protection on components like tanks and gas bottles.

- EMI and RF shielding on plastic components and only an electric arc spray gun are used for the process.

- Electrical conductance on insulators and capacitor end caps with the help of an electric arc spray gun only.

Safety Precautions of Metalizing Wire Spray:

- The precautions against fumes and dust hazards. Wearing a mask, hand gloves, gumboot, and proper ventilation should be observed.

- Any warning printed on containers by the manufacturers should be observed and the user should consult in all cases of doubt regarding health hazards & fire hazards arising from the product.

- The grit blasting machine process, and metalizing operation should be carried out in dry weather conditions.

- Metal spray coating should be applied without any delay and contamination on surfaces such as oil, grease, dirt removed before application of sealer coat.

- No special health hazards arise during the metalizing spray wire if wearing proper PPE.

Advantages of Metalizing Wire Coating

- To achieve insulation

- Resistance to corrosion

- Significant cost advantages

- Not subject to degrading

- Anodic protection of surface

- Stronger adhesion than paint

- Longer lasting than paint

- Faster and more productive

- Surface roughness no more than 0.05 mm

- Pure metals and alloys can be sprayed

- Can be operated under extreme temperature conditions

Disadvantages of Metalizing Wire Coating

- Disguises the substrate – In many cases the metalizing wires coatings are so efficient. It is very difficult to tell what material the equipment was made of after the thermal spray coating process unless stringent records are kept.

- Precisely effectiveness evaluation – once the thermal spray wire coating has been applied it is very difficult to identify exactly how well the coating has gone on, other than by a visual assessment.

- Costly setup – some thermal spray coatings methods require different types of thermal spray guns that are very expensive and result in a high initial setup cost of the coating process.

Industries Uses Metalizing Wire for Sale

- General industry

- Aviation

- Automotive

- Electronics

- Food process business

- Part business

- Marine engineering business

- Hydraulic line conduit

- heat-exchanger conduit

- Propulsion motors

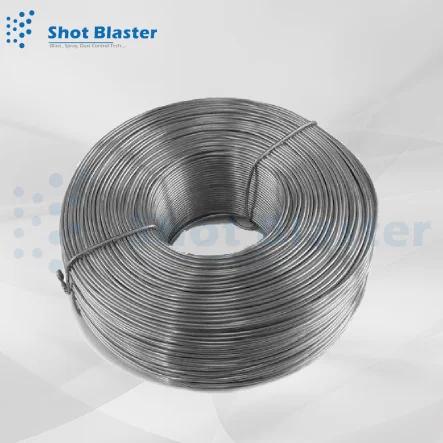

Metalizing Wire Available Packing Details

- 30 Kg constant lengths coils have no loose turns.

- 100-250Kg Drum pack.

- 13.50Kg in plastic spools

Metalizing Wire Price in India

Sand blast is the most significant metalizing wire manufacturer's in India, we provide metalizing wire price in India for sale. The metalizing wire is widely used in many industries to protecting equipment from corrosion and has no maintenance cost. We also manufacture sand blasting machines, portable shot blasting machine, shot blasting machines, sand blasting hopper, flame spray gun, zinc wire, mixing tube, sandblasting nozzle, pinch valve, copper slag, glass beads, steel shots, steel grit, etc. Metalizing wire price in India provides metalizing wire sizes from 1.5 mm to 4mm.