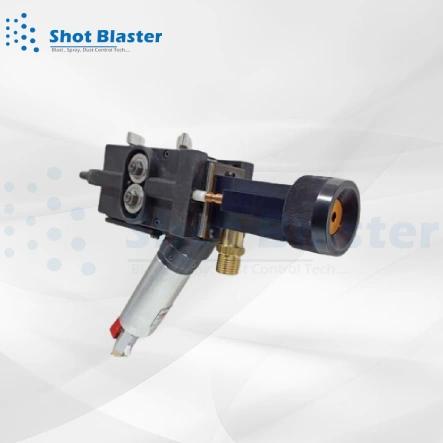

Arc Spray Gun

In the Metal Arc Spray Gun process, the raw material in the form of metallic wires is melted by means of an electric arc spray Gun. The molten material is atomized by compressed air and propelled towards the workpiece and components. Arc Spray Process is a technique in which Electric Arc Wire Spraying is done by the Twin Arc Spray Gun.

Working of Arc Spray Gun

Twin Wire arc spray Gun uses two consumable wires of metal to fed inside the gun independently. These wires are charged and then an arc is generated between them. The heat from this arc melts the incoming wires of metal. After that this molten metal entrained in an air jet from the gun. Arc Spray Coating has entrained molten metal deposited onto the workpiece with the help of compressed air. This process mostly used for heavy coating of metallic on a workpiece.

Arc Spray Gun Specifications

| Applications / Usage |

Industrial |

| Air Pressure |

50-70 psi |

| Nozzle Size |

2 mm |

| Air Consumption |

9-10 cfm |

| Air Inlet |

3/8 " |

| Minimum Quantity |

1 piece |

Arc Spray Gun

In the Arc spray gun process, the common material inside such a metallic wire is liquefied by methods for an electrical arc. The liquid material is atomized by compacted air and pushed towards the workpiece. The coatings gave inside the arc spraying strategy normally have a more prominent porosity and lower attachment power than those got from another thermal spray gun, making them of nearly more unfortunate property. Be that as it may, for a couple of purposes, higher proportions of porosity are worthy or possibly wanted. The arc spray gun includes a complete scope of business purposes.

Arc Spray Gun Manufacturer Process

Arc spray gun utilizes two metallic wires as the covering of crude materials. The two wires are electrically accused of switching extremity and stay taken care of into the arc spray gun, which consistently controls its speed. Arc spray gun manufacturer utilizes two consumable wires of metal to take care of inside the gun independently. These wires are charged then an arc is created between them. The warmth from this arc disappears the approaching wires of metal, at that point this warmed metal entrained in an air spray from the gun. This entrained liquid metal moved onto the workpiece with the assistance of compacted air. This process regularly utilized for substantial covering of metallic on a workpiece.

Applications of Arc Spray Gun Manufacturer

- Manufacture components that exhibit specific surface characteristics.

- Use less costly substrate materials for components, yet maintain high-performance surface properties.

- Improve component service life.

- Repair existing components to like-new or better than new condition.

- Salvage mismachined components.

- Provide a high-performance bond coat in a coating system.

Benefits of Arc Spray Gun

- No combustible gas supply is required.

- Versatile, reliable, and easy to operate.

- High production spray rates.

- Produces easily to machine coatings.

Industrial Uses

- Power Generation.

- Waste Incineration.

- Electronics.

- Automotive.

- Aerospace.

- Oil/Gas / Petrochemical.

- Paper/Printing.

- Steel/Metal Production.

- General Industry.

- Glass /Optics.

Arc Spray Gun Manufacturer in India

We are the leading Arc Spray Gun Manufacturer in India and we provide all solutions for Arc Spray processes and Flame Spray Gun. We have proven reliable & promise to our customers that we offer a complete package of Arc Spray Equipments. Our focus is to improve the Arc Spray Gun in terms of Efficiency of spraying, Proficiency coating, etc. Some of the parameters we are still working to provide full flesh solutions towards the Arc Spraying techniques.

- Delivery Time- Minimum Time

- Port Of Dispatch- Thar Dry Port

- Production Capacity- 2-3 Per Month

- Packaging Details- Box

- Payment Terms- L/C (Letter of Credit)/T/T (Bank Transfer)